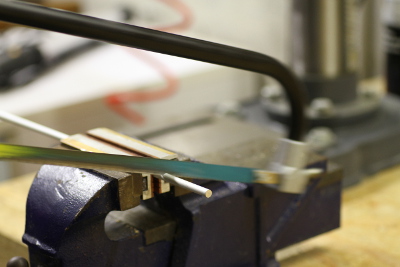

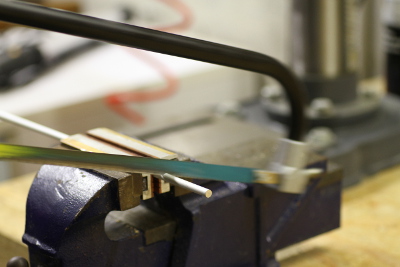

Cutting an aluminum rod with a hacksaw.

Cutting small rods or pipes with the hacksaw is something that I do quite often. On any kind of materials: steel, aluminum, copper, brass, various plastics, wood,... Here is a little trick to obtain nice flat and square faces without a lathe.

Cutting an aluminum rod with a hacksaw.

But the resulting cut surface is very rough and not esthetic. One can still file it by hand to smoothen it down a bit, but it's hard to obtain a flat and square surface.

The face of the rod after cutting with the hacksaw.

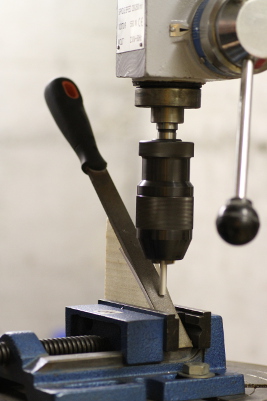

If you have a lathe on hand, than facing the surface is very simple and provides excellent results. But even without a lathe, you can still insert your rod or pipe in a drill-press and "drill" against a flat file. On my drill press, I can fit any diameter from 1.5 to 13 mm in its chuck, which is often enough (for me).

Facing the rod on the drill-press by "drilling" against a

flat file.

Just clamp the file in the vice and make sure it's level and square to the drill axis. Since both the file and the vice are made of hardened still, it's always a good idea to put some soft material between them: I use two pieces of cardboard. Use a high rotation speed, higher than the speed you would use for drilling. Soft materials like aluminum or plastic tend to stick on the file: it's not a big deal, just have a metal brush handy to clean it.

As one can see in the picture below, the result is not perfect but pretty good.

The face of the rod after facing it in the drill-press.

If you want, you can also add a little chamfer to the face by installing the file ate 45°. I use a small wooden 45° shim to align and hold the file in the vice. In fact, as you push with the drill-press, the force on the file is quite large: without the wooden shim, the file tends to move down in the vice.

Chamfering the rod on the drill-press by "drilling" against

a flat file tilted at 45°.

After facing and chamfering this 6 mm diameter aluminum rod, this is the final result:

The face of the rod after chamfering it in the drill-press.

Again, the result is not perfect, but much better than just filing it down by hand.

| Home | Mechanics | Page hits: 013981 | Created: 10.2014 | Last update: 10.2014 |